BACK

METALLURGY

BACK

METALLURGY

As a well-known engineering company in China, Sinosteel MECC has made outstanding contributions to the development of Chinese metallurgical industry by accomplishing over 500 national key projects for giant Chinese steel producers. Being one of the first "go global" companies in China, Sinosteel MECC enjoys high reputation in overseas metallurgical engineering market.

3050m3 blast furnace for ISDEMIR, Turkey

Scope: complete blast furnace system (excluding pig machine and TRT)

Main technical features:

3x2350m3 blast furnace for Cangzhou Zongheng

3x2350m3 blast furnace for Cangzhou Zongheng

Scope: engineering, equipment supply, civil construction and installation.

Main technical features: 1) material screening before charging and nut coke recovery to BF; 2) serial type bell-less top, designed top pressure 0.2~0.25MPa; 3) BF life-span (without medium repair) ≥ 15 years; 4) flat double cast houses with 3 tap holes, no slag hole; 5) rotary top combustion HBS, combustion air and gas preheated, designed blast temperature 1200℃~1250℃, HBS life-span ≥30 years; 6) dry type bag filter dedusting for top gas, TRT; 7) INBA slag granulation system, 100% water granulated slag; 8) three parallel injection tanks for PCI, main pipe+distributor tpe, designed injection capacity 200~220kg/t iron.

265m2 sinter plant for Baosteel Bayi Iron & Steel Co., Ltd.

Main technical features:

300m2 sinter plant for ISDEMIR, Turkey

Scope: engineering, equipment supply, training, installation and commissioning instruction and test

Main technical features:

Slab caster project for TOSYALI, Turkey

Scope: 130t EAF, 130t LF, 2-strand slab caster

Main technical features: 1) EAF tpe:AC-EAF; 2) shell diameter:7000mm; 3) tapping quantity: 130t/heat; 4) EAF transformer: 145MVA; 5) raw material: scrap; 6) production: 1.15mtpa; 7) product: carbon steel; 8) slab size: 880mm x 170mm

120t LF for ERDERMIR, Turkey

120t LF for ERDERMIR, Turkey

The project was designed to produce 170 million tons of liquid steel with double positions and double ladle dars, applying advanced secondary refining technology. Sinosteel MECC supplied basic engineering of project, detailed engineering and equipment of LF, installation and commissioning instruction. Project runs in stable condition after being put into production, which is highly recognized by customer.

1.2mtpa bar/rod wire mill for ICDAS, Turkey

1.2mtpa bar/rod wire mill for ICDAS, Turkey

Main technical features:

Designed capacity: 1.2mtpa bar

Product specification: 8-50mm rebar. High production with dual lines. 25 stands of advanced high rigidity short stress rolling mills developed by Sinosteel MECC meet the requrements of small size bar slitting rolling.

Maximum rolling speed: 18m/s, reaching world advanced technology and equipment level.

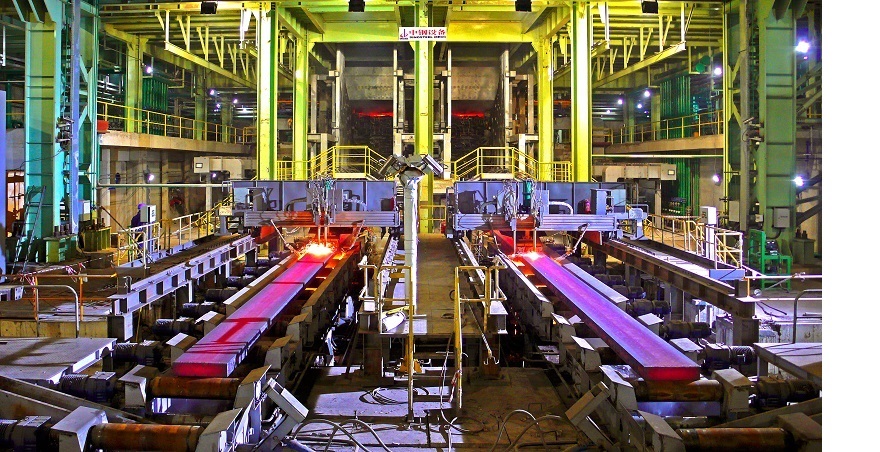

950mm hot strip rolling project for TOSYALI, Turkey

950mm hot strip rolling project for TOSYALI, Turkey

Scope: engineering, equipment supply, installation and commissioning

Capacity: annual production of 1.05mtpa hot coil, 1.1mtpa slab; second phase 1.5mtpa hot coil.

Main features: China's own intellectual-property right hot strip rolling technology was applied for the project which was the first one exported by China of its kind, with world advanced level technology and euqipment level.

4100mm heavy plate rolling project for Chongqing Iron & Steel Co., Ltd.

4100mm heavy plate rolling project for Chongqing Iron & Steel Co., Ltd.

Scope: engineering, equipment supply, civil construction, installation and commissioning