BACK

100,000-Cubic-Meter Gas Holders of Blast Furnace and Converter Delivered to JSW

BACK

100,000-Cubic-Meter Gas Holders of Blast Furnace and Converter Delivered to JSW

Recently, the 100,000m3 gas holders contracted by Sinosteel Equipment & Engineering Co., Ltd. (Sinosteel MECC) on EPC basis of a blast furnace and a converter for JSW Steel have been put into operation successfully, declaring another “first” record by Chinese company in India.

The JSW Group is a part of the O. P. Jindal Group with strong footprints across core economic sectors, namely, Steel, Energy, Mining, Petroleum, Natural Gas and Infrastructure. The flagship company of JSW Group, JSW Steel has become India’s leading integrated steel manufacturer with a capacity of 22MTPA.

Since Sinosteel MECC’s first presence in India in 2005, a long term and friendly cooperation relationship has been maintained with JSW after a number of projects, including JSW Salem 500,000tpa heat recovery coke ovens, JSW Vijayanagar 1.5mtpa and 1.9mtpa stamp charging coke ovens with by-product, JSW Dolvi 1mtpa stamp charging coke ovens (5.5-meter) with 140t/h CDQ, in production, as well as the 3mtpa stamp charging coke ovens (6.25-meter) with 2 sets of 190t/h CDQ under construction. Sinosteel MECC is qualified and stable contractor and spare parts supplier of JSW Steel.

above: 1.5mtpa coke ovens with by-product for JSW Vijayanagar, completed in 2009

below: 1mtpa coke ovens (5.5-meter) for JSW Dolvi, completed in 2014

On March 2018, Sinosteel MECC won the bid of contracting JSW Dolvi’s first -- 100,000m3 gas holders of blast furnace and converter on EPC basis. This is also the first blast furnace and converter gas holders supplied by Chinese company in India. JSW is convinced to accept Chinese membranes instead of Europeans by the evidence-based technical analysis of Sinosteel MECC.

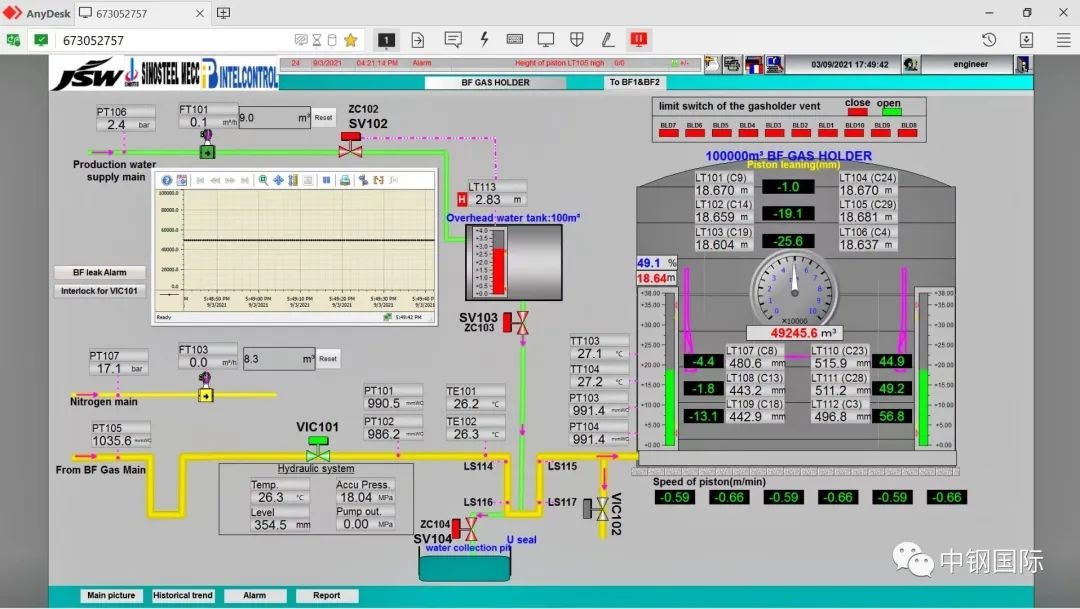

The project kicked off in November 2018 and blast furnace gas holder started operation in August 2021, while converter gas holder is completed in August 2022.

operating data satisfies the design demand

The large and energy-saving diaphragm gas holders are completely China-made and witnesses the first application of the key part-single diaphragm. The single diaphragm BF and converter gas holders have excellent performance and are user-friendly for operation and maintenance. They may save operation cost by more than 50% per year compared with oil sealing and recover the gas for further use.

At the meantime, the application of single diaphragm gas holder of 100,000m3 has to overcome many difficulties—

Fabrication of diaphragm

For single diaphragm gas holders, the 100,000m3 volume is large scale. The length of diaphragm will reach 20 meters long, which is close to the ceiling of manufacturer capacity, and means high cost and requirement on the diaphragm quality.

Challenges to working pressure and pistonThe working pressure of converter gas holder is 2000Pa while the lowest engineering working pressure in China is 3000Pa, which put new demand on the intensity of piston—to strike a balance between weight and pressure bearing.

Afterall, the diaphragm arrived at site in August 2019 and maintains in good sealing condition after three years in spite of high temperature.

Sinosteel MECC breaks up the monopoly of European companies in India with the success of 100,000m3 BF and converter gas holders and gains thumbs-up from JSW for another satisfactory cooperation.